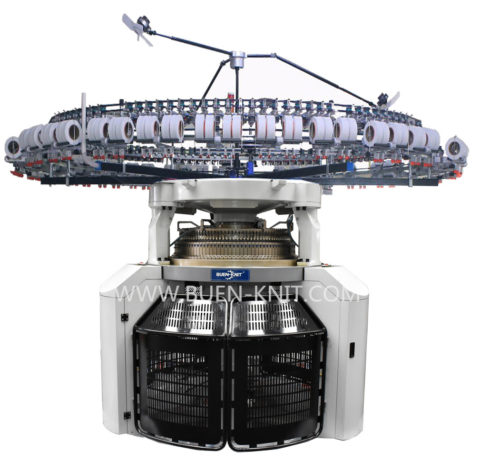

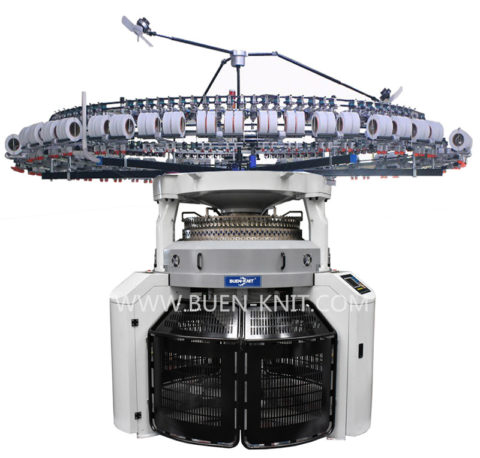

Double Jersey Interlock Circular Knitting Machines

Model HFDI Diameter 30-44" Gauge 16-40G Feeder 72F-108F Motor 5.5-7.5KW

- Machine description

- Double Jersey Interlock Circular Knitting Machine install with two tracks CAMs on the dial plate and four tracks CAMs in the cylinder,through adjusting the position of CAMs, machine can knit various fabrics such as twill, interlock fabric, air layer fabrics, little jacquard interlayer gasket, bubble-bubble, crape,knitting cloth, pique fabric etc.. If the double jersey machine install lycra feeders and attachments, it can also knit stretch double jersey fabric.All types of fabrics produced by the machine are widely used in producing underwear, varied sportswear and fashion fabrics and industrial fabrics etc.

- Originally, the interlock knitting machine had needles of two different lengths, long needles knitting in one cam-track and short needles knitting in a track nearer to the needle heads. Long needle cams were arranged for knitting at the first feeder and short needle cam at the second feeders. The needles were set out alternately in each bed, with long needles opposite to short needles. At the first feeder, long needles in cylinder and dial knit , and at the second feeder short needles knit together; needles not knitting at a feeder follow a run-through track.

- Machine Features

- Double jersey interlock machine cylinder is stainless steel imported from Japan, which make sure the cylinder have high quality and good performance.

- We use steel ball runway structure with oil immersion to make the bed plate of double jersey interlock knitting machine, which make sure the machine running stable and smoothly, low noise and high abrasion resistant.

- Components for drive system of interlock knitting machine is made by superior material through high efficient heat treatment. Gear and other main components are made in Taiwan and bearing are imported from Japan. All of these make the machine with high precision drive system, low running noise and stable operation.

- Product application

underwear, coat fabrics, varied sportswear and fashion fabrics etc.

- Fabric Samples

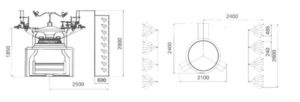

- Machine Dimension

- Standard Equipment List

Well designed machine body frame

Steel ball wire supported main drive system

Groz-beckert Germany brand needles

Kern-libers Germany brand sinkers

Central and individual stitch control adjustment system

Japanese stainless steel cylinder

Standard side stand tube creels(aluminium or pvc)

Positive feeders NPF/TPF/MPF

Lycra feeders Memminger brand or China brand

Individual cylinder cam box for each feeder

Inverter motor controller

Mechanical fabric taken down system(rolling, folding)

Anti-dust devices fan Top-3 & Middle-2

fabric spreader

Integrated main power control panel with 3 shift counters

Digital revolution counter

oiler lubricator air spray type or electronic type

Needle broken detectors

yarn carriers guiders Ceramic tip

Tools box with tools

Spare parts include needles/sinkers/feeders/yarn guider etc