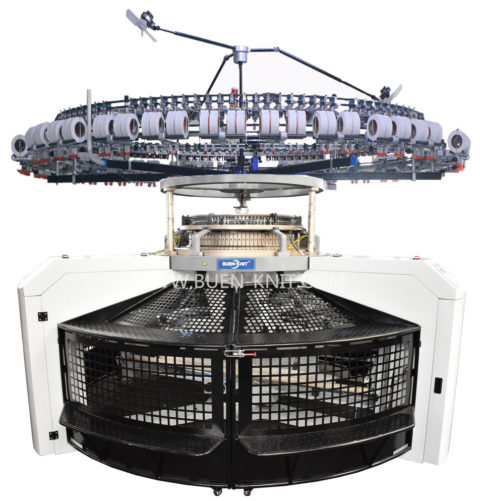

High Speed Four Track Single Jersey Circular Knitting Machines

Model: HFSJ Diameter: 12-44" Gauge: 16-44G Feeder: 3F/4F/6F Per inch Motor: 2.2-7.5KW

- Machine description

- Single jersey circular knitting machine install with four tracks CAM design in the cylinder. Adjusting the position of the cams(knit, tuck and miss), machine will knit different kinds of fabric such as plain single jersey, lycra single jersey,single pique, french terry, mini-jacquard etc. The single jersey knitting machine can be suitable for processing material such as cotton, polyester, silk, chemical fiber,blended yarn of various specifications etc. The single jersey machine also can be changed to three thread fleece knitting machine by changing the knitting parts like cylinder, sinkers, cam, yarn guider.

- Most single jersey fabrics is produced on single jersey ciruclar knitting machine whose latch needle cylinder and sinker ring revolve throught the stationary knitting cam systems that, together with their yarn feeders, are situated at regular intervals around the circumference of the cylinder. The yarn is supplied from cones, placed on a free-standing creel, throught tensioners, stop motions and guide eyes down to the yarn feeder guides.

- Machine Features

- Sinkers and cams for single jersey circular knitting machine are made of special alloy steel. An ideal knitting machine running at stable activity to get the production as well as perfect output of faultless fabrics.

- Cylinder for single jersey machine are designed with the function which can auto clear cotton dust specially, avoid stopping machine to clear the dust frequently.

- Single jersey knitting machine normally equip 3 feeder per inch , and it can be also make 4 feeder or 6 feeder per inch.

- The machine adopt central stitch control system which can move the cylinder very easily. So that workers can change the fabric weight very easy.

- CAM in high precision are interchangeable to speed up transformation of different pattern organizations.

- Drive system components for single jersey machine are made by superior material through high efficient heat treatment. Gear and other main components are imported from Taiwan and bearing are imported from Japan. All of these make sure the machines to be with high precision drive system, low running noise and stable operation.

- The bed plate is made of steel ball runway structure with oil immersion,by this to make sure the machine have stable running, low noise and high abrasion resistant.

- Motor, invertor, lubricator and other components are German, Japan or Taiwan brands, which can be customerized.

- Product application

T-shirt, polo shirt, underwear, swimwear, sportwear, gym suit, tights etc

- Fabric Samples

- Machine Dimension

| Diameter | Net Weight(kg) | Gross Weight(kg) | Wooden Case Size(cm) |

| 40″-44″ | 2400 | 2600 | 240x230x220 |

| 36″-38″ | 2200 | 2400 | 230x223x220 |

| 30″-34″ | 2000 | 2200 | 230x220x220 |

| 12″~28″ | 1800 | 2000 | 200x200x200 |

- Standard Equipment List

Well designed machine body frame

Steel ball wire supported main drive system

Groz-beckert Germany brand needles

Kern-libers Germany brand sinkers

Central and individual stitch control adjustment system

Japanese stainless steel cylinder

Standard side stand tube creels(aluminium or pvc)

Positive feeders NPF/TPF/MPF

Lycra feeders Memminger brand or China brand

Individual cylinder cam box for each feeder

Inverter motor controller

Mechanical fabric taken down system(rolling, folding)

Anti-dust devices fan Top-3 & Middle-2

fabric spreader

Integrated main power control panel with 3 shift counters

Digital revolution counter

oiler lubricator air spray type or electronic type

Needle broken detectors

yarn carriers guiders Ceramic tip

Tools box with tools

Spare parts include needles/sinkers/feeders/yarn guider etc