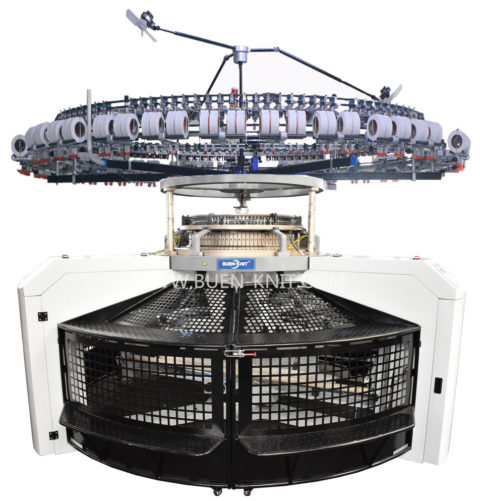

Single Jersey Open Width Knitting Machine

Model HFOW Diameter 30-44" Gauge 16-32G Feeder 90-132F Motor 3.7-7.5KW

- Machine Description

Single jersey open width knitting machine is designed based on the single jersey tubular knitting machine. By installing the special open width fabric taken down device, the fabric can be cutted automatically on the open width machines. This is to makes sure the fabric to be more smooth and without wrinkles. Fabric knitted from this machine can be used without waste, which can save the factory cost. Open width knitting machine equip with 4 tracks of CAM, it can knit many types of knited fabric such as plain single jersey, spandex single jersey, pique, locasted, mini jacquard etc.

- Machine Features

- Single jersey open width knitting machine designs to enable the fabric completely not have crease. Make sure the fabric can be used completely without waste, which can reduce the cost and enhance the profit.

- If you choose dual-size for single jersey open width knitting machine,it can interchange the diameter in one machines.For example: 34″ 102 feeders can be interchanged with 30″ 90 feeders.

- The micro-adjustment of the CAM box makes the distance between the CAM and the cylinder can be controlled.

- The fabric taken down system equip drum speed transfer device, which makes the fabric in even and stable density. it’s easy control and save your time.

- Single jersey open width knitting machine equip auto stop device, when fabric cut is not complete, machine will stop automatic

- Various spring-loaded detector points. These are carefully positioned around the cylinder according to their particular function. A pointer is tripped to stop the machine by a fault or malfunctioning element such as a yarn slub, fabric lamp, needle head, latch spoon, etc.

- Single jersey open width knitting machine can fix the tightness of different size fabric, which extend the life of needle.

- Distance between two fabric ends keep same when producing fabric.

- Machine have scale marks, which can made record when production.

- Product Application

T-shirt, polo shirt, underwear, swimwear, sportwear, gym suit, tights etc

- Fabric Samples

- Machine Dimension

| Diameter | Net Weight(kg) | Gross Weight(kg) | Wooden Case Size(cm) |

| 40″-44″ | 3000 | 3200 | 340x230x225 |

| 36″-38″ | 2800 | 3000 | 330x230x225 |

| 30″-34″ | 2600 | 2800 | 320x220x225 |

- Standard Equipment List

Well designed machine body frame

Steel ball wire supported main drive system

Groz-beckert Germany brand needles

Kern-libers Germany brand sinkers

Central and individual stitch control adjustment system

Japanese stainless steel cylinder

Standard side stand tube creels(aluminium or pvc)

Positive feeders NPF/TPF/MPF

Lycra feeders Memminger brand or China brand

Individual cylinder cam box for each feeder

Inverter motor controller

Mechanical fabric taken down system(rolling,cutting)

Anti-dust devices fan Top-3 & Middle-2

fabric spreader

Integrated main power control panel with 3 shift counters

Digital revolution counter

oiler lubricator air spray type or electronic type

Needle broken detectors

yarn carriers guiders Ceramic tip

Tools box with tools

Spare parts include needles/sinkers/feeders/yarn guider etc