Weft knitted stitches from circular knitting machines described so far have been composed entirely of knitted loops. A knitted loop stitch is produced when a needle receives a new loop and knocks over the old loop that it held from the previous knitting cycle. The old loop then becomes a needle loop of normal configuration.

Other types of stitch may be produced on each of the four-needle arrangement base structures by varying the timing of the intermeshing sequence of the old and new loops. These stitches may be deliberately selected as part of the design of the weft knitted structure or they may be produced accidentally by a malfunction of the knitting action so that they occur as fabric faults. When these stitches are deliber- ately selected, a preponderance of knitted loop stitches is necessary within the struc ture in order to maintain its requisite physical properties.

The needles generally produce knitted loop stitches prior to the commencement, and at the termination, of these selected stitches, and there are usually certain needles that are knitting normally during the same cycles as those in which these stitches are produced.

Apart from the knitted loop stitch, the two most commonly-produced stitches are the float stitch and the tuck stitch. Each is produced with a held loop and shows its own particular loop most clearly on the reverse side of the stitch because the limbs of the held loop cover it from view on the face side.

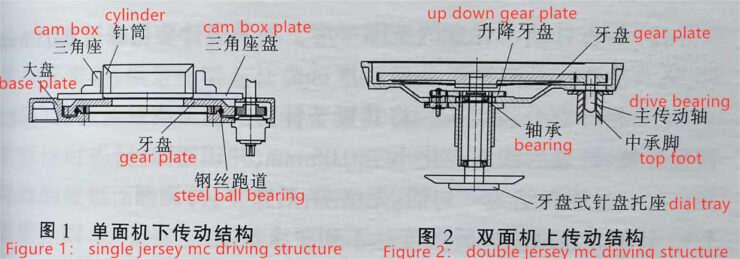

The operation process of the circular knitting machines is essentially a movement process in which the parts rotate in the circular direction, and most of the parts are installed and run around the same center of the circle. After a certain period of operation, the machines in the knitting factory need to be overhauled. In […]

Weft knitted stitches from circular knitting machines described so far have been composed entirely of knitted loops. A knitted loop stitch is produced when a needle receives a new loop and knocks over the old loop that it held from the previous knitting cycle. The old loop then becomes a needle loop of normal configuration. […]

Changes of dimension after knitting can create major problems in garments and fabrics, expecially those produced from hydrophilic fibers such as wool and cotton.Articles knitted from synthetic thermoplastic fibers such as nylon and polyester can be heat-set to a shape or to dimensions that are retained unless the setting conditions are exceeded during washing and […]

Chiffon knitted fabric on circular knitting machine, also known as georgette (from France georgette), georgette, is a strong twist crepe, crepe weave a silk fabric. Warp and weft with S twisting and Z twisting two different twist strong grab yarn, according to 2S, 2Z arranged between the phases to plain weave, the weft density of […]

Computerised Jacquard Circular Knitting Machine offer the decisive advantages of convenient power-supply, compatibility with existing mechanical components, mirco-miniaturisation of circuitry, and economical data storage. In addition, computerised system do not require to be of a size proportionate to their task or to operate on a one-to-one ralationship with it. Computerised selection or machine control is […]

The sinkers for knitting machine is the second primary knitting element(the needle being the first). It is a thin metal plate with an individual or a collective action operating approximately at right angles from the hook side of the needle bed, between adjacent needles. It may perform one or more of the following functions, dependent […]