Computerised Jacquard Circular Knitting Machine offer the decisive advantages of convenient power-supply, compatibility with existing mechanical components, mirco-miniaturisation of circuitry, and economical data storage. In addition, computerised system do not require to be of a size proportionate to their task or to operate on a one-to-one ralationship with it. Computerised selection or machine control is […]

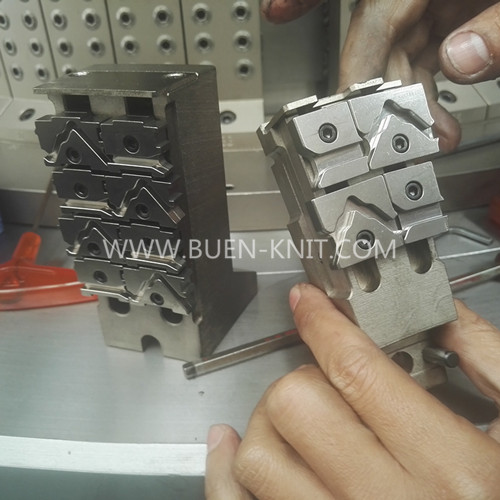

The sinkers for knitting machine is the second primary knitting element(the needle being the first). It is a thin metal plate with an individual or a collective action operating approximately at right angles from the hook side of the needle bed, between adjacent needles. It may perform one or more of the following functions, dependent […]

The simplest rib fabric made by Double Jersey Rib Circular Knitting Machines is 1×1 rib. Rib has a vertical cord appearance because the face loop wales tend to move over and in front of the reverse loop wales. As the face loops show a reverse loop intermeshing on the other side,1×1 rib has the appearance […]

Double cylinder purls circular knitting machine makes purl structure fabric which have one or more wales which contain both face and reverse loops. This can be achieved with double-ended latch needles or by rib loop transfer from one bed to the other, combined with needle bed racking. The semi-circles of the needle and sinker loops […]

Single jersey knitting machines whose latch needle cylinder and sinker ring revolve through the satationary knitting cam systems that, together with their yarn feeders, are situated at regular intervals around the circumference of the cylinder. The yarn is supplied from cones , placed either on an integral overhead bobbin stand or on a free-standing creel, […]

8 Eight lock interlock knitting machines makes the fabric is a 2×2 version of interlock that maybe produced using an arrangement of two long and two short needles, provided all the tricks are fully cut through to accommodate them and knock-over bits are fitted to the verges to assist with loop formation on adjacent needles […]

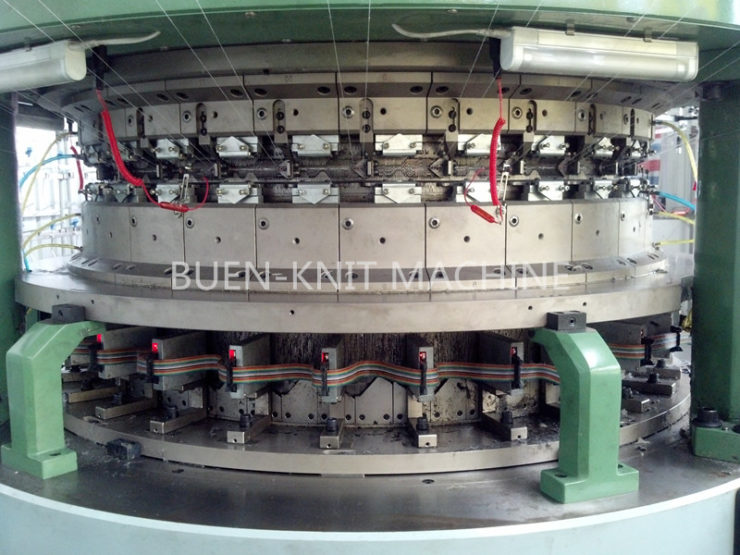

Interlock Circular Knitting Machine normally must have the followings: 1 Interlock gating, the needles in two beds being exactly opposite each other so that only one of the two can knit at any feeder. 2 Two separate cam systems in each bed, each controlling half the needles in an alternate sequence, one cam system controlling […]

The preferred method today for making three thread fleece fabric is to use a top needle butt and cam-track for knitting the ground(face) and tie-in (binding) yarns, and four tracks and corresponding buts positions(which can be arranged) for the fleece tucking sequence. Below are the steps for production of a three thread fleece circular knitting machines. […]

Four primary base weft knitted structures–plain, rib, interlock and purl–are the base structures from which all weft knitted fabrics and garments are derived. Each is composed of a different combination of face and reverse meshed stitches, knitted on a particular arrangement of needle beds. Each primary structure may exist alone, in a modified form with […]

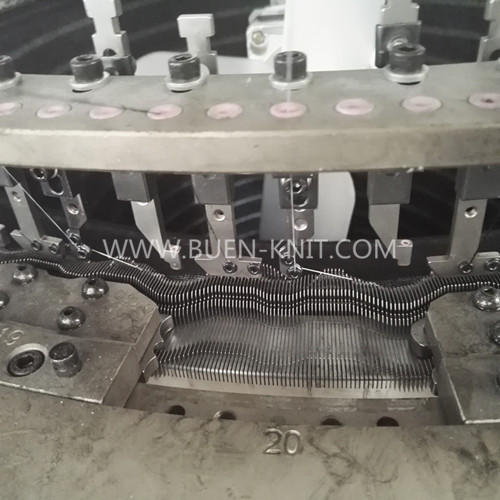

1 The rest position. The head of the needle hook is level with the top of the verge of the trick. The loop formed at the previous feeder is in the closed hook. It is prevented from rising as the needle rises, by holding-down sinkers or web holders that move forward between the needles to […]

- 1

- 2