Double cylinder purls circular knitting machine makes purl structure fabric which have one or more wales which contain both face and reverse loops. This can be achieved with double-ended latch needles or by rib loop transfer from one bed to the other, combined with needle bed racking.

The semi-circles of the needle and sinker loops produced by the reverse loop intermeshing tend to be prominent on both sides of the structure and this has led to the terms” links-links” being generally applied to purl fabrics and machines.

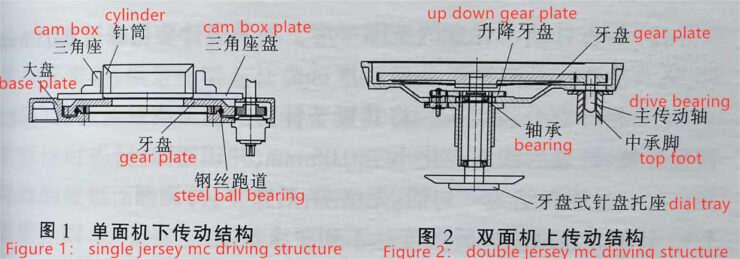

The tricks of the two needle beds in double cylinder purls circular knitting machine are exactly opposite to each other and in the same plane, so that the single set of purl needles, each of which has a hook at eigher end, can be transferred across to knit outwards from either bed. Knitting outwards from one bed, the needle will produce a face meshed needle loop with the newly-fed yarn whilst the same needle knitting outwards with its other hook from the opposite bed will produce a reverse meshed needles loop.

As the needles in double cylinder purls circular knitting machine moves across between the two needle beds, the old loop slides off the latch of the hook that produced it and moves along the needle towards the other hook. It can not enter because it will pivot the latch closed.(an action that must notoccur until the new yarn has been fed to that hook)

The needle hook that protrudes form the bed knits with the yarn whilst the hook in the needle trick acts as a butt and is controlledd by and element termed a slider. There is a complete set of sliders with their noses facing outwards from each bed. It is the sliders whose butts are controlled by the knitting and needle transfer cam system in each bed and they, in turn, control the needles.