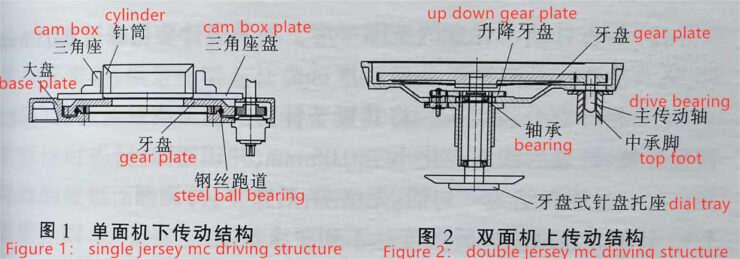

The simplest rib fabric made by Double Jersey Rib Circular Knitting Machines is 1×1 rib.

Rib has a vertical cord appearance because the face loop wales tend to move over and in front of the reverse loop wales. As the face loops show a reverse loop intermeshing on the other side,1×1 rib has the appearance of the technical face of plain fabric on both sides until stretched to reveal the reverse loop wales in between.

1×1 rib is production of by two sets of needles from double jersey rib circular knitting machines, which being alternately set or gated between each other. Relaxed 1×1 rib is theoretically twice the thickness and half the width of an equivalent plain fabric, but it has twice as much width-wise recoverable stretch. In practice, 1×1 rib normally relaxes by approximately 30 per cent compared with its knitting width.

1×1 rib is balanced by alternate wales of face loops on each side; it therefore lies flat without curl when cut. It is a more expensive fabric to produce than plain and is a heavier structure; the double jersey rib circular knitting machines also requires finer yarn than a similar gauge plain machine. Like all weft knitted fabrics, it can be unroved from the end knitted last by drawing the free loop heads through to the back of each stitch. It drawn in one direction and the others in the opposite direction, whereas the loops of plain are always withdrawn in the same direction, from the technicial face to the technicial back.

Rib can not be unroved form the end knitted first because the sinker loops are securely anchored by the coress-meshing between face and reverse loop wales. This characteristic, together with its elasticity, makes rib particularly suitalbe for the extremities of articles cushas tops of socks, cuffs of sleeves, rib borders of garments, and stolling and strapping for cardigans. Rib fabrics from double hersey rib circular knitting machines are elastic, form-fitting, and retain warmth better than plain structures.