Speciality fabrics include fleecy, plush, high pile and wrap fabrics. Although some constructions are unique to a single type of circular knitting machines, others may be knitted on a range of machinery.

The surface effects of fleecy, plush or pile are developed during the finishing process usually on the technical back of single faced fabric.

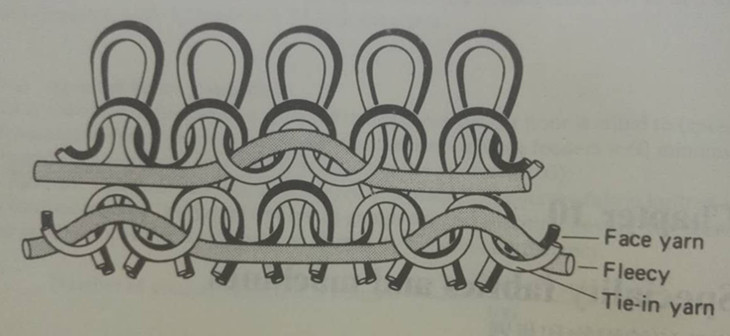

In fleecy fabrics, the fleece yarn fibres(usually in the form of inlaid yarn) become entangled and indistinguishable from the base yarn on the effect side, despite having been separately supplied druing knitting.

In pile and plush structures the pile and plush is clearly distinguishable from the base. Pile is considered to stand out at right-angles to the base, whereas plush lies at less of an angle from the base surface. High quality three-thread invisible fleecy and sinker loop terry(plush plating) are still produced on a rapidly declining number of old loopwheel and sinkerwheel frames respectively, but they are facing intense competition from modern, high-speed, more productive, single-jersey, latch needle machines.

Invisible fleecy is a plain plated structure composed of a face and binding yarn with a fleecy backing yarn tucked into the technical back at every fourth wale to mesh only with the binding yarn. The face yarn prevents the arms of the fleecy tucks being visible between the wales on the face, which would spoil its clean appearance. The fleecy inlay is spread across the technical back by centring the fleecy tucks of the next three-feed sequence on the middle of the threeneedles that missed the fleecy yarn in the previous sequence.

A popular gauge for sweat shirts and track suits is E 20, USING 1/28’s to 1/30’s(NeB) cotton or acrylic yarn or 1/70’s nylon and 1/9’s to 1/12’s cotton or acrylic fleece yarn. A 30 inch diameter three-thread fleece circular knitting machine will give a finished width of 54-60 inches(1.37m-1.52m). The loosely-twisted fibres of the fleece yarn responde easily to napping during finishing.

The standard sweatshirt weight is 250-300 g/suqure meter.