Originally, the terms”machine” used to refer to a mechanism on a beared needles frame such as fashioning mechanism on the straight bar frame. Today, it refers to the complete assembly

A knitting machine is thus an apparatus for applying mechanical movement, either hand or power derived, to primar knitting elements, in order to convert yarn into knitted loop structures.

The machine incorporates and co-ordinates the action of a number of mechanisms and devices, each performing specific functions that contribute towards the efficiency of the knitting action.

The main features of a knitting machine are as follows:

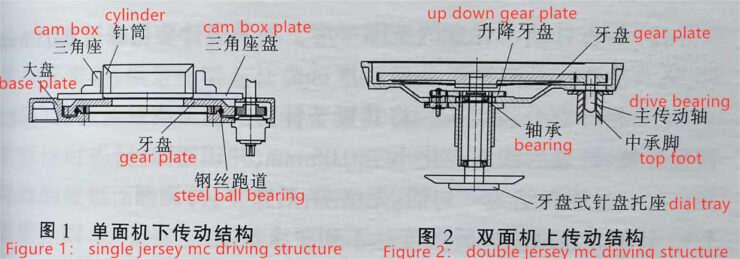

- The frame or carcass, normally free standing and either circular or rectilinear according to needle bed shape, provides the support for the majority of the machines’s mechanisms.

- the machine control and drive system co-ordinates the power for the drive of the devices and mechanisms.

- The yarn supply consists of the yarn package or beam accommodation, tensioning devices, yarn feed control and yarn feed carriers or guides.

- The knitting system includes the knitting elements, their housing, drive and control, as well as associated pattern selection and garment-length control device(if equipped).

- The fabric take-away mechanism includes fabric tensioning, wind-up and accommodation devices.

- The quality control system includes stop motions, fault detectors, automatic oilers and lint removal systems.

Machines may range from high-production, limited-capability models to versatile, multi-purpose models having extensive patterning capabilities. the more complex the structure being knitted, the lower the knitting speed and efficiency. The simplest of the knitting machines would be hand-powered and manipulated whereas power-driven machines may be fully automatically-programmed and controlled from a computer system.