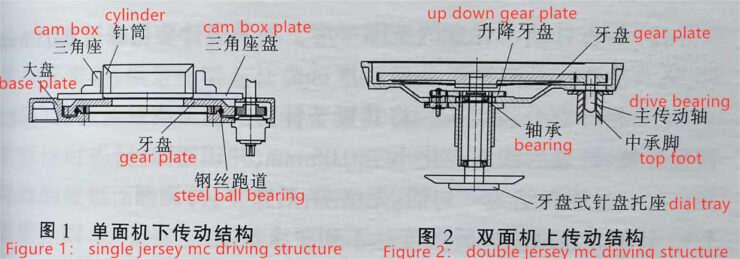

Interlock Circular Knitting Machine normally must have the followings:

1 Interlock gating, the needles in two beds being exactly opposite each other so that only one of the two can knit at any feeder.

2 Two separate cam systems in each bed, each controlling half the needles in an alternate sequence, one cam system controlling knitting at one feeder, and the other at the next feeder.

3 Needles set out alternately, one controlled from one cam system, the next from the other, diagonal and not opposite needles in each bed knit together.

Originally, Interlock Circular Knitting Machine had needles of two different lengths, long needles knitting in one cam-track and short needles knitting in a track nearer to the needle heads. Long needle cams were arranged for knitting at the first feeder and short needle cams at the second feeder. The needles wre set out alternately in each bed, with long needles opposite to short needles. At the first feeder, long needles in cylinder and dial knit, and at the second feeder short needles knit together; needles not knitting at a feeder follow a run-through track. On modern machines the needles are of the same length.

As only alternate needles knit at a feeder, Interlock Circular Knitting Machine can be produced in finer gauges then rib, with less danger of press-offs. Interlock knitting is, however, more of a problem than rib knitting. Because productivity is half, less feeders can be accomodated, and there are finer tolerances. When two different color yarn are used, horizontal stripes are produced if the same color is knitted at two consecutive feeders, and vertical stripes if odd feeders knit one colour and even feeders knit the other colour. The number of interlock pattern rows per inch is offen double the machine gauge in needles per inch.